Body material: Aluminum(GB-ADC12)+PC(Japan Brand)

Power supply: USA Brand High Efficient Solar Panel

Battery: NI-MH1.2V/600MAH; Lithium battery3.2V/500MAH(Made in Japan);

Resistance: >30T

LED Color: White, Yellow, Blue, Red, Green

Size: L125mm*W107mm*H26+50mm

Body material: Casting Aluminium alloy +PC

Power supply: 5V/80MAH Mono crystalline silicon

Battery: Lithium battery3.2V/1000MAH

Resistance: >40T(can be installed in the middle of road)

LED Color: White, Yellow, Blue, Red, Green

Size: φ125*50mm

Body material: PC

Power supply: Solar panel(Monocrystalline 2.5V /0.2W)

Battery: NIMH 600MAH

Resistance: >20T(static)

LED Color: White, Yellow, Blue, Red, Green

Size: φ117*23mm

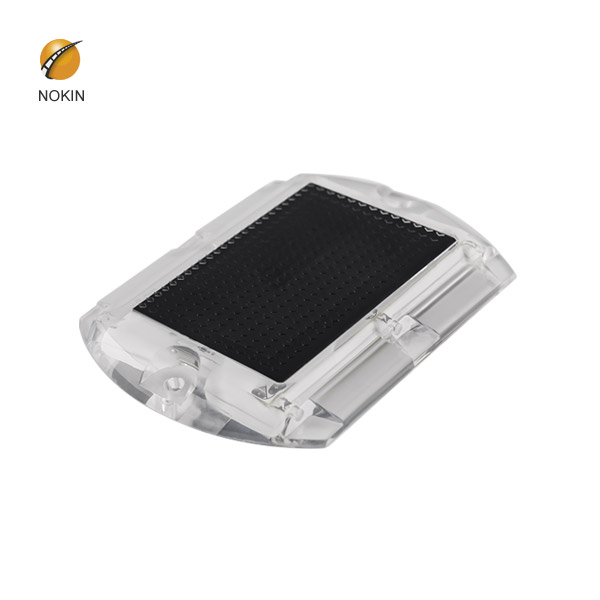

Body material: PC

Power supply: High efficient solar panel(5V/60mA)

Battery: Lithium battery(3.2V/500mAh)

Resistance: 15T

LED Color: White, Yellow, Blue, Red, Green

Size: 114*90*11mm

Body material: Hi-pressure Casting Aluminium alloy

Power supply: Solar panel(monocrystalline 2.5V/0.2W)

Battery: NI-MH 1.2V/800MAH or lithium battery

Resistance: >20T(static)

LED Color: White, Yellow, Blue, Red, Green

Size: L104*W104*H20mm

Body material: Hi-pressure Casting Aluminium alloy

Power supply: Solar panel(Monocrystalline 2.5V /0.2W)

Battery: NI-MH1.2V/800MAH

Resistance: >20 Tons

LED Color: White, Yellow, Blue, Red, Green

Size: L123*W133*H22mm+55mm

Body material: Aluminum Alloy+PC cover

Power supply: Solar panel(Monocrystalline 2.5V /120MA)

Battery: Lithium battery 1000MAH*3.2V

Resistance: >30 Tons

LED Color: White, Yellow, Blue, Red, Green

Size: Ф123*45mm

Body material: Cast Aluminum

Power supply: Solar panel(Monocrystalline 2.5V /0.2W)

Battery: NI-MH 1.2V/800MAH

Resistance: >30 Tons

LED Color: White, Yellow, Blue, Red, Green

Size: Ф120*50mm(bottom)

Ф135*50mm(upper)

Body material: Heavy duty casting aluminium

Power supply: Solar panel(monocrystalline 2.5V/0.2W)

Battery: NI-MH 1.2V/800MAH

Resistance: >20T(static)

LED Color: White, Yellow, Blue, Red, Green

Size: L129*W114*H23mm+53mm

Body material: Aluminum+PC

Power supply: Mono crystalline solar panel

Battery: NI-MH 1.2V/ 600mah(high temperature resistance);

Resistance: >20T(static)

LED Color: White, Yellow, Blue, Red, Green

Size: 125*43*30mm

Body material: Tempered Glass/PC

Power supply: USA Brand High Efficient Solar Panel

Solar panel(Monocrystalline 2.5V /0.2W)

Battery: NI-MH1.2V/600MAH(high temperature resistance, made in China)

Lithum battery3.2V/500MAH(made in Japan)

Resistance: >20T

LED Color: White, Yellow, Blue, Red, Green

Size: φ112*56mm

Body material: Hi-pressure Casting Aluminium alloy

Power supply: Solar panel(monocrystalline 2.5V/0.2W)

Battery: NI-MH 1.2V/800MAH

Resistance: >20T(static)

LED Color: White, Yellow, Blue, Red, Green

Size: L104mm*W94mm*H20mm

.jpg)

Discover the differences between solar and reflective road studs to improve road safety. Learn how to choose the right option for better visibility, durability, and cost-efficiency. Contact us for customized road safety solutions.

.jpg)

Explore the latest innovations in solar road studs in 2024, featuring high-efficiency solar panels, advanced energy storage, IoT integration, and sustainable design. Discover how these cutting-edge technologies enhance road safety, reduce accidents, lower maintenance costs, and promote global energy conservation and emission reduction efforts.

.jpg)

Explore how solar road studs enhance road safety, visibility, and sustainability. Powered by renewable energy, these durable, cost-effective, and easy-to-install solar markers provide bright LED illumination for safer nighttime driving, reduce carbon footprints, and support sustainable urban development. They are ideal for highways, bike lanes, parking lots, and pedestrian crossings.

.jpg)

Solar road studs are an innovative and energy-efficient road safety solution, offering enhanced visibility and sustainability. Designed for highways, intersections, tunnels, and rural roads, they are durable, weather-resistant, and cost-effective. Embrace solar-powered road studs to improve safety while promoting eco-friendly infrastructure solutions.

.jpg)

The future development trend of solar road studs will be jointly driven by multiple factors such as technological innovation, market demand, and environmental protection policies. With the continuous advancement of technology and the continuous expansion of the market, solar powered road studs will play a more important role in urban traffic management and make greater contributions to urban traffic safety and environmental protection.

.jpg)

Correct installation of solar road reflectors is a prerequisite for ensuring that they can operate stably. Only solar LED road studs installed according to the correct steps can ensure that they can provide people with clear road guidance as planned and improve road safety.